■What is AOP2.0?

AOP 2.0 is a system which can degrade non-biodegradable components by free radicals generated by key technology of nano bubble combined with other technologies such as UV ( ultra violet ray ) , O3,electrolysis, photo catalyst and pressurization.

■Oily water E,S(Oil-water electrical separation device)is a device to separate the oil and water by electricity ,even though chemicals are usually used in usual method . Sulfuric acid band is used to assist when machining oil is treated.

■Hybrid Type is the system which can control the electrodes of OWES by the controller of AOP⁺.

Especially, waste water which contains variety type of components is effectively treated by Hybrid Type.

■Proper positon

It is ideal if there are neutralization tank or biological treatment tank.

When it is used by itself, neutralization tank and aggregation tank should be put after tanks of AOP⁺ and OWES.

■Capacity to treat

Approximately 5 tons can be treated . We propose the best solution to each clients.

▶AOP⁺Sylinder

AOP⁺ has been designed to generate active fee radicals (・OH) and attack targets effectively as

Ultra Fine Bubble put pressure to the water and electricity excite reactions of photocatalyst.

Those are the reason why chemical reaction are much improved.

There are more than 100,000,000(1hundred million) nano-sized bubbles per ml.

These enhance effectiveness of treatment.

NaClO and H₂O₂ are used for the purpose of promoting reaction in AOP.

They might not be used depends on conditions of waste water as we usually decide it according to the result of pre test.

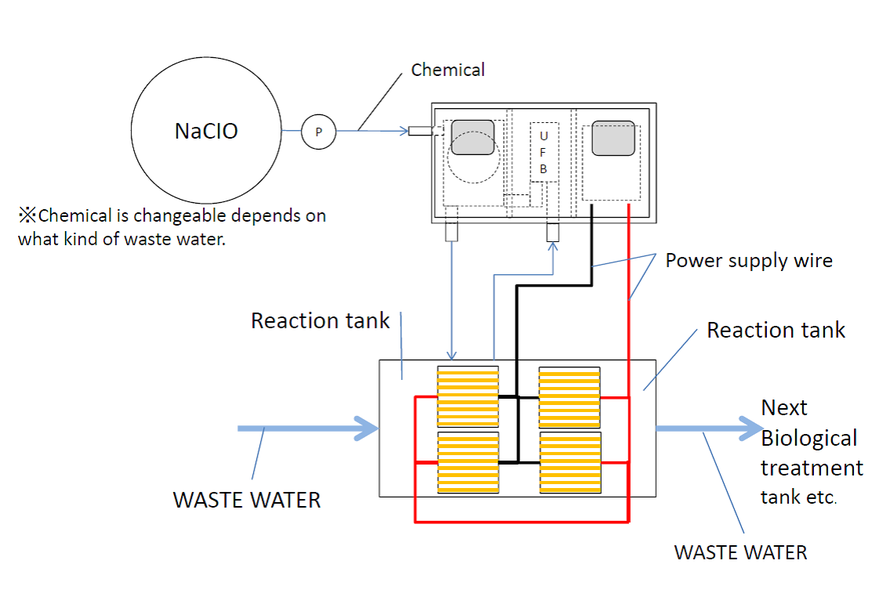

▶Electrode

NaCIO and H2O2 are used for the purpose of promoting reaction in AOP.

They might not be used depends on conditions of waste water as we usually decide it according to the result of pre test.

This electrode is the type to sink in water.

Unitized electrode is less power consumption.

Electrode of cylinder shape can electrolysis efficiently as its surface area is wide.

Since electrode is independent, material of electrode can be chosen by condition of waste water.

Further more, there is enough space to set up sludge removal device on the top space of the

tank inside

▶ Flow chart

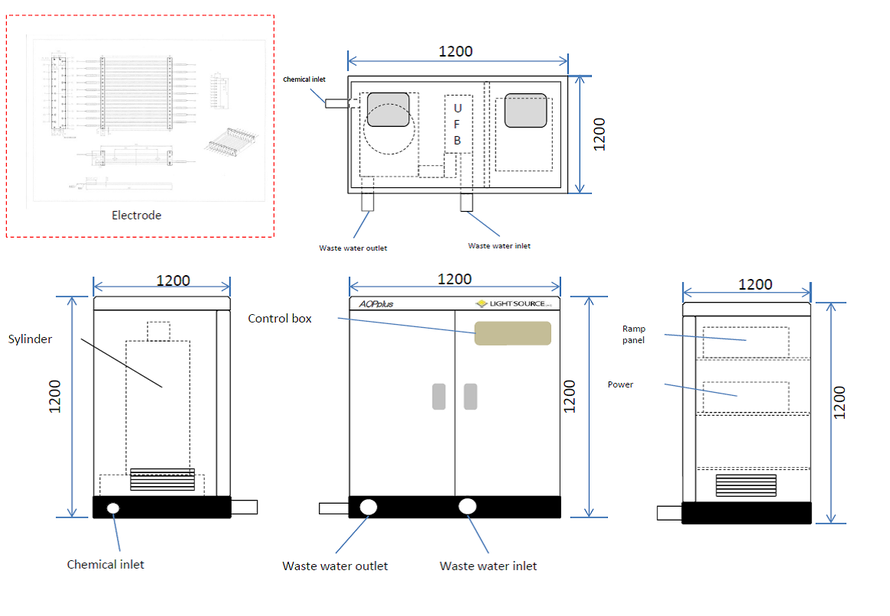

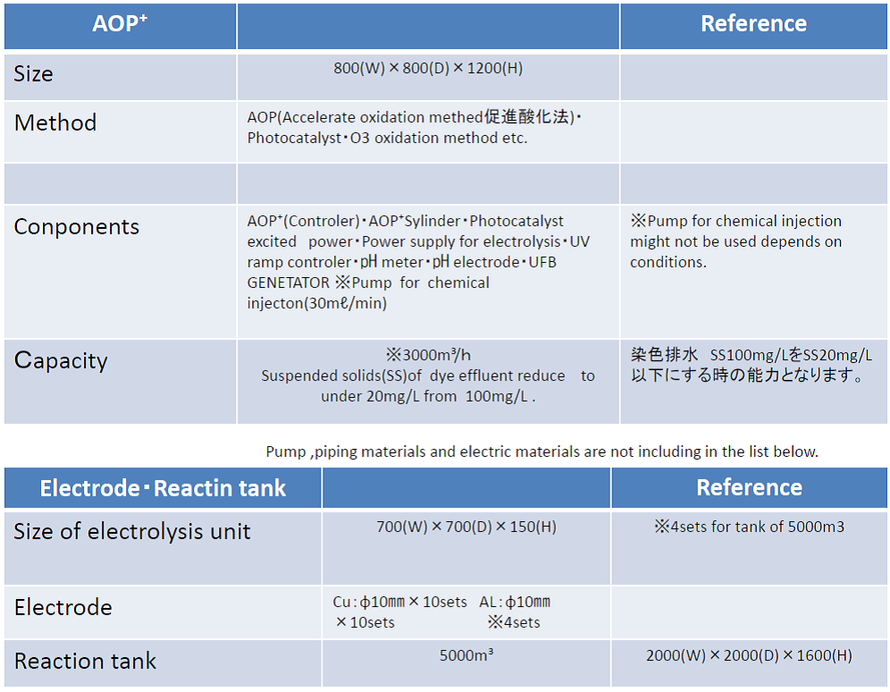

▶Appearance of AOP

▶Specification

▶Sterilization test Results of UV for bacillus

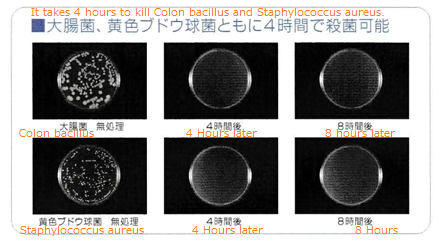

▶Steralization test Results of Light catalyst for bacillus

LIVINGENERGIES & Co.

kaminagakubo,Nagaizumi-cho,Suntou-gun,411-0935 JAPAN

KOJI TAKAHASHI( MR.)

EMAIL: info@livingenergies.biz

TEL +81‐55-956-3384

FAX +81‐55-988-5929